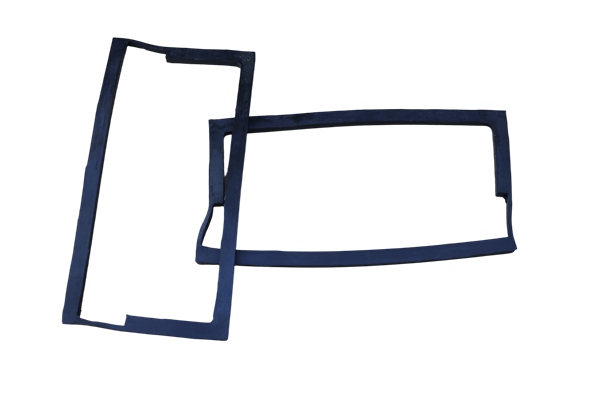

Custom-Molded Rubber Gasket

The Custom-Molded Rubber Gasket is a precision-engineered sealing solution tailored to meet the unique requirements of industrial, automotive, aerospace, plumbing, and electronic applications. Unlike standard off-the-shelf gaskets, this pro...

The Custom-Molded Rubber Gasket is a precision-engineered sealing solution tailored to meet the unique requirements of industrial, automotive, aerospace, plumbing, and electronic applications. Unlike standard off-the-shelf gaskets, this product is manufactured through custom mold development, ensuring a perfect fit for specialized equipment, irregular surfaces, or unique sealing scenarios. Crafted from high-grade rubber materials (EPDM, neoprene, nitrile, silicone, Viton, or custom blends) selected for specific environmental and operational needs, it delivers exceptional leak-proof performance, resistance to harsh conditions, and long-term durability. Designed to seal gaps between mating surfaces, prevent fluid/gas leakage, and block contaminants, the custom-molded gasket is ideal for equipment manufacturers, maintenance teams, and industries requiring precise, reliable sealing solutions that align with their unique design specifications. Whether for high-pressure machinery, extreme-temperature systems, or chemical-resistant applications, this custom solution combines versatility, precision, and performance to enhance operational efficiency and safety.

Core Features

1. Tailored Mold Design for Perfect Fit & Functionality

Each Custom-Molded Rubber Gasket is developed using a custom mold engineered to match the exact dimensions, shape, and surface profile of your application. Our engineering team collaborates with clients to analyze design drawings, 3D models, or physical samples, ensuring the gasket’s inner/outer diameters, thickness, bolt holes, grooves, bevels, or irregular contours are replicated with micron-level precision. This tailored approach eliminates gaps, misalignments, or compression inconsistencies common with standard gaskets, delivering a snug, leak-proof seal that optimizes equipment performance. Whether for complex flanges, custom valves, specialized enclosures, or unique component interfaces, the custom mold ensures the gasket integrates seamlessly with your system, reducing installation time and minimizing the risk of sealing failure.

2. Premium Rubber Material Selection for Targeted Performance

We offer a wide range of high-grade rubber materials, each selected to address specific environmental and operational challenges:

EPDM: Ideal for outdoor, water, or HVAC applications, offering superior weather, ozone, and UV resistance.

Neoprene: Excels in oil, chemical, and abrasion resistance, suitable for industrial machinery, hydraulic systems, and automotive underhood components.

Nitrile (Buna-N): Delivers excellent resistance to fuels, lubricants, and petroleum-based fluids, perfect for fuel systems, pumps, and plumbing.

Silicone: Provides extreme temperature stability (-60℃ to +230℃) and food-grade compliance, ideal for high-heat equipment, medical devices, and kitchen appliances.

Viton: Offers exceptional chemical resistance to acids, solvents, and corrosive gases, designed for harsh industrial processes and aerospace applications.

Custom Blends: Engineered for unique requirements (e.g., anti-static, flame-retardant, or high-pressure resistance) to meet specialized industry standards.

All materials undergo rigorous testing to ensure compatibility with your application’s temperature range, pressure levels, and chemical exposure.

3. Superior Sealing Performance & Durability

The custom-molded design, combined with premium rubber materials, ensures the gasket delivers exceptional sealing performance and long-term reliability:

Leak-Proof Protection: The precise fit and compressible rubber structure create an airtight/watertight seal, preventing leakage of fluids (water, oil, fuel) or gases (air, chemicals) even under dynamic pressure or temperature fluctuations.

Compression Recovery: Exhibits excellent compression set resistance, maintaining its shape and sealing integrity after repeated assembly/disassembly or prolonged pressure exposure.

Environmental Resistance: Withstands extreme temperatures, chemical corrosion, UV radiation, moisture, and abrasion, ensuring durability in harsh operating conditions.

Mechanical Strength: Engineered to resist tearing, stretching, and deformation, even in high-vibration or high-pressure applications, extending the service life of your equipment.

4. Flexible Customization & Streamlined Production

We offer comprehensive customization options to meet your specific needs:

Dimensions & Shape: Accommodates any size (from micro-gaskets for electronics to large flanged gaskets for industrial pipelines) and shape (circular, rectangular, irregular, or complex 3D profiles).

Special Features: Integrates custom design elements such as bolt holes, recessed grooves, beveled edges, textured surfaces, or reinforcement layers (e.g., fabric inserts for high-strength applications).

Volume & Lead Time: Supports low-volume prototypes, medium production runs, and high-volume manufacturing with efficient lead times, ensuring timely delivery for your project or production schedule.

Industry Compliance: Manufactured to meet international standards (ISO 9001, RoHS, REACH, FDA, ASME B16.21) and industry-specific certifications (e.g., aerospace, medical, or automotive standards) as required.

5. Easy Installation & Cost-Effective Solutions

Designed for user-friendly installation, the Custom-Molded Rubber Gasket requires no specialized tools or modifications to your equipment. Its precise fit ensures quick alignment and assembly, reducing downtime during maintenance or production. While custom-molded gaskets involve initial mold development, they offer long-term cost savings by eliminating the need for makeshift sealing solutions, reducing equipment damage from leaks, and minimizing replacement frequency. Our team provides end-to-end support, from design consultation and mold development to production and quality control, ensuring a seamless experience and a final product that meets or exceeds your expectations.

Quality Assurance

Our Custom-Molded Rubber Gaskets adhere to strict quality control protocols throughout the manufacturing process. Each batch undergoes rigorous testing, including dimensional accuracy checks (using 3D scanning and coordinate measuring machines), leak testing, compression set tests, temperature resistance tests, and chemical compatibility tests. The mold development process includes prototype validation to ensure the gasket meets your design specifications before full-scale production. We source materials from trusted suppliers and maintain ISO 9001-certified manufacturing facilities to guarantee consistency, reliability, and compliance with industry standards.

Whether you need a custom gasket for a new product design, replacement of obsolete parts, or a solution for a unique sealing challenge, our Custom-Molded Rubber Gasket delivers precision, performance, and durability tailored to your needs. Partner with us to enhance your equipment’s reliability, reduce maintenance costs, and ensure optimal sealing performance in any application.